What Are the Different Types of Chandlier

Chandelier manufacturers produce diverse lighting types including crystal chandeliers, modern chandeliers, traditional chandeliers, outdoor lighting solutions, custom chandeliers, baroque chandeliers, and chandelier lowering systems. Each category serves specific design aesthetics and functional requirements, from luxury residential installations to commercial hospitality projects requiring specialized mechanical systems.

Type of Chandlier

At XIYI Lighting, we manufacture the complete spectrum of chandelier categories to address every design vision and technical requirement. Whether you need handcrafted crystal chandeliers for luxury hotels, weather-resistant outdoor lighting for architectural projects, or innovative lowering systems for high-ceiling installations, our experienced engineering team and advanced manufacturing capabilities ensure we can deliver customized solutions that exceed your expectations and project specifications.

- Crystal Chandeliers – Premium handcrafted crystal lighting fixtures featuring Austrian Swarovski crystals and Bohemian crystal components with modular design systems for easy assembly and maintenance, offering over 200 size and style combinations.

- Custom Chandeliers – Bespoke lighting solutions for luxury projects with personalized designs, custom dimensions, and specialized finishes to meet unique architectural requirements and interior design visions.

- Traditional Chandeliers – Classic and contemporary designs incorporating timeless elegance with modern LED technology, featuring brass, bronze, and gold finishes with customizable configurations for various room sizes.

- Baroque Chandeliers – Ornate historical reproduction lighting fixtures with intricate detailing and elaborate decorative elements, perfect for luxury hotels, palaces, and high-end residential applications requiring dramatic visual impact.

- Outdoor Lighting Solutions – Weather-resistant LED and traditional lighting systems with IP65 waterproof rating, marine-grade stainless steel components, and smart control integration compatible with WiFi, Zigbee, and Bluetooth protocols.

- Chandelier Lowering Systems – Advanced mechanical lifting systems with German engineering precision, dual-cable safety redundancy, smartphone app integration, and whisper-quiet operation for easy maintenance of high-ceiling installations.

- Decorative Lamps – Artistic lighting collections featuring contemporary designs, premium materials, and innovative LED integration with high-CRI chips for superior color rendering and 50,000-hour lifespan testing.

Our Services for Chandlier

XIYI Lighting provides end-to-end chandelier manufacturing solutions tailored for luxury lighting distributors and retailers. We specialize in custom crystal chandelier design and production, offering complete OEM/ODM services from initial concept sketches to final packaging. Our services include precision crystal cutting using German equipment, multi-stage electroplating with premium finishes, integrated LED module assembly in clean room facilities, and specialized chandelier lowering system manufacturing. We handle all technical certifications (CE, UL, RoHS), provide detailed CAD drawings for approval, execute quality control testing at every production stage, and offer flexible packaging solutions for safe international shipping.

- German Precision Equipment

- Austrian Crystal Partnerships

- 20+ Years Experience

- Patent Portfolio Technology

- ISO 9001 Certified

The Manufacturing Process of Chandlier

Chandelier manufacturing is a complex multi-stage production process that combines artistic design, precision engineering, and quality craftsmanship to create luxury lighting fixtures. Professional chandelier manufacturers integrate advanced machinery, premium materials like Austrian crystal and marine-grade metals, with specialized techniques including electroplating, LED integration, and mechanical assembly systems to produce custom lighting solutions for residential and commercial applications.

- Design and Engineering – Initial concept development, technical drawings, and structural calculations for custom chandelier specifications

- Material Sourcing and Quality Inspection – Procurement of premium components including Austrian crystal, Czech Bohemian glass, marine-grade stainless steel, and high-CRI LED modules with incoming quality verification

- Crystal Cutting and Processing – Precision cutting using German-imported equipment with 0.1mm tolerance, followed by hand-cutting and polishing by skilled craftsmen for European-standard crystal quality

- Metal Framework Fabrication – CNC machining and welding of chandelier arms, central body, and mounting hardware using marine-grade stainless steel (316L grade)

- Electroplating and Surface Treatment – Multi-stage electroplating process with chromium, nickel, and gold finishing using 8-tank electroplating systems for corrosion resistance

- LED Module Integration – Clean room assembly of LED components with Samsung and Cree high-CRI chips (Ra>95) for superior color rendering and 50,000-hour lifespan

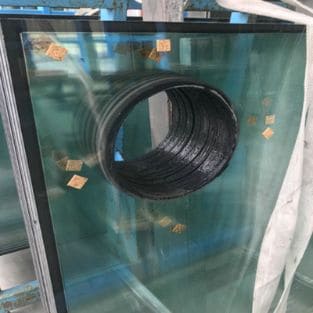

- Mechanical System Assembly – Installation of hydraulic lowering mechanisms with German engineering precision, dual-cable safety systems, and remote control technology

- Crystal and Component Assembly – Hand-attachment of individual crystal elements, glass shades, and decorative components with modular design principles

- Electrical Wiring and Testing – Professional wiring installation with safety compliance to CE, UL, and RoHS standards, followed by electrical continuity testing

- Quality Control and Burn-in Testing – 72-hour burn-in testing, photometric verification, and IP65 waterproof testing for outdoor lighting models

- Final Inspection and Packaging – Complete functional testing, aesthetic inspection, and museum-quality packaging to prevent transit damage

- Certification and Documentation – Third-party testing by TUV, SGS, and Intertek laboratories with complete certification documentation for international compliance

Our Qingdao facility harnesses cutting-edge technology to produce Chandlier with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Chandlier

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Chandlier

Although chandeliers are often seen as luxury items, our prices are significantly lower than those in your local market. By eliminating middlemen and leveraging our advanced production capabilities, we provide exceptional value without compromising on quality. Warranty and Support - Fees for extended warranty coverage or premium support services.

- Product Cost – The base price of the chandelier, which varies based on size, design, and materials.

- Customization Fees – Additional charges for bespoke designs or modifications to standard models.

- Shipping and Handling – Costs for packaging and transporting the chandelier to your location.

- Customs Duties and Taxes – Import fees that may apply depending on your country’s regulations.

- Installation Costs – Expenses for professional installation, which can vary based on the complexity of the chandelier.

- Accessories and Extras – Optional items like chandelier lowering systems or additional crystal components.

- Warranty and Support – Fees for extended warranty coverage or premium support services.

Frequently Asked Questions

What defines quality in crystal chandelier manufacturing?

Premium crystal chandeliers require hand-cut crystals (like Austrian Swarovski or Bohemian glass), precision metal frameworks, and meticulous assembly. Quality indicators include UL/CE certifications, corrosion-resistant finishes, and modular designs for maintenance. XIYI LIGHTING uses 0.1mm-tolerance cutting and 316L stainless steel for lasting elegance in custom chandeliers.

Which modern chandelier styles dominate luxury interiors?

Transitional designs blending crystal with matte black/matte white metals (e.g., Solaris Orb) are trending, along with minimalist linear pendants and artisanal glass shapes. Sustainable LED integration is essential. XIYI offers 200+ customizable configurations with high-CRI LEDs for contemporary spaces.

How critical is professional chandelier installation?

Essential for fixtures over 22 lbs (like Regis chandeliers) due to ceiling load limits and electrical safety. Professional installers ensure proper wiring, chain support, and sloped-ceiling adaptations. XIYI provides hydraulic lowering systems with 500kg capacity for safe maintenance.

Can chandelier manufacturers customize finishes and sizes?

Yes, leading brands like Crystorama and XIYI offer bespoke options—oil-rubbed bronze, antique gold, or matte finishes—plus scalable dimensions. Modular designs (e.g., Broche collection) enable easy component swaps. XIYI’s 8-tank electroplating line ensures durable, custom-colored finishes.

What specifications suit outdoor chandeliers?

Require IP65 waterproof ratings (-40°C to 60°C tolerance), marine-grade steel, and damp-location UL listing. Seeded/alabaster glass diffuses light evenly. XIYI’s outdoor collections feature 15-year anti-corrosion warranties and smart-control integration.

How to maintain crystal chandeliers long-term?

Use microfiber cloths with ammonia-free cleaners monthly. Avoid harsh chemicals that damage crystal refraction. Inspect sockets yearly and replace bulbs with matching wattage LEDs. XIYI includes crystal-polishing kits and modular replacement parts with every fixture.

What distinguishes premium chandelier manufacturers?

Artisanal craftsmanship (hand-cut crystals, wrought-iron frames), ISO 9001 certification, and third-party testing (TUV/SGS). Brands like Schonbek and XIYI use museum-quality packaging and provide photometric reports. XIYI offers 5-stage quality control with 72-hour burn-in testing.

Are sustainable practices important in lighting manufacturing?

Yes—energy-efficient LED designs, solar-powered factories (like Crystorama’s NY facility), and RoHS-compliant materials are now expected. XIYI uses recyclable packaging and Samsung/Cree LEDs with 50,000-hour lifespans to reduce environmental impact.

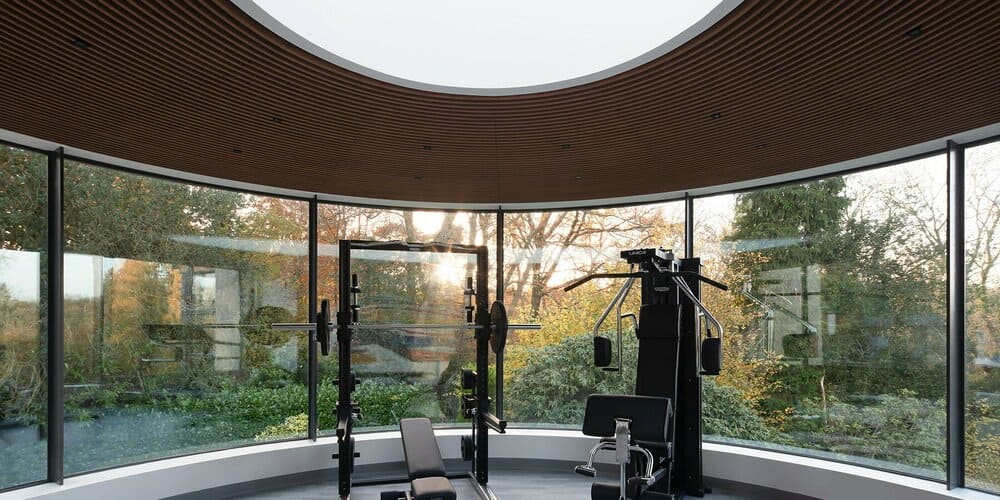

Which chandeliers work best for high-ceiling commercial spaces?

Large-scale designs (40″+ diameter) with 12+ lights, like Zodiac or Abbott collections, plus lowering systems for maintenance. Load-rated chains and commercial UL listings are mandatory. XIYI engineers project-specific solutions for hotels and lobbies with 500kg-capacity mechanics.

Why choose crystal over glass for chandeliers?

Lead crystal (24%+ PbO) refracts light with superior prismatic effects compared to standard glass. Hand-faceted cuts enhance sparkle. XIYI sources Czech Bohemian crystal and Swarovski elements for 99% light transmittance in luxury projects.

Which finishes are trending in luxury chandeliers?

Antique gold, matte black, and brushed nickel dominate, often with two-tone metal accents (e.g., Alston’s chain detail). Oil-rubbed bronze suits traditional spaces. XIYI’s PVD coatings provide scratch-resistant finishes in 15+ custom hues.

How to illuminate small spaces with chandeliers?

Mini-chandeliers (17″-24″ width) like Norwalk or Paris Market add elegance without overwhelming rooms. Use flush mounts for low ceilings. XIYI’s compact designs include damp-rated options for bathrooms and adjustable rods for sloped ceilings.

Chandlier Application Scenarios

Chandeliers illuminate diverse settings from luxury hotels to modern homes, requiring specialized designs for each environment. Premium manufacturers like XIYI LIGHTING tailor fixtures to meet technical demands (IP ratings, load capacity) and aesthetic trends (crystal, minimalist, or smart-enabled styles), ensuring functionality and elegance across residential, commercial, and outdoor applications.

Luxury Hospitality Venues

High-end hotels and resorts use crystal chandeliers as grand focal points in lobbies or ballrooms. Fixtures require UL certification, high weight capacity (e.g., 500kg hydraulic systems), and custom designs matching architectural themes. XIYI crafts bespoke pieces with Austrian Swarovski crystals for global luxury chains

Outdoor Entertaining Areas

Patios and gardens utilize damp-rated (IP65) fixtures with marine-grade steel frames. Brands like Vaxcel offer bronze/nickel finishes and seeded glass shades for weather resistance (-40°C to 60°C), ideal for pergolas or poolside settings

Residential Statement Lighting

Dining rooms and foyers feature chandeliers like Crystorama’s Solaris Orb or Paris Market, blending hand-cut crystals with matte black/white metals. Modular designs allow size adjustments (17″-40″+ diameters), while LED integration ensures energy efficiency

We Are Always Provide Best Chandlier For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Chandlier Related Articles

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.